There was lots of good information and practical hands-on work at the EAA SportAir Workshops this weekend. The Museum of Flight Restoration Center at Paine Field (Everett, WA) makes for a great venue.

Sling builders were well represented, with 3 active projects and at least a couple prospective Sling TSi-leaning workshop attendees. It was nice to see and chat with fellow builder Philip Rueker, taking part in the Electrical course.

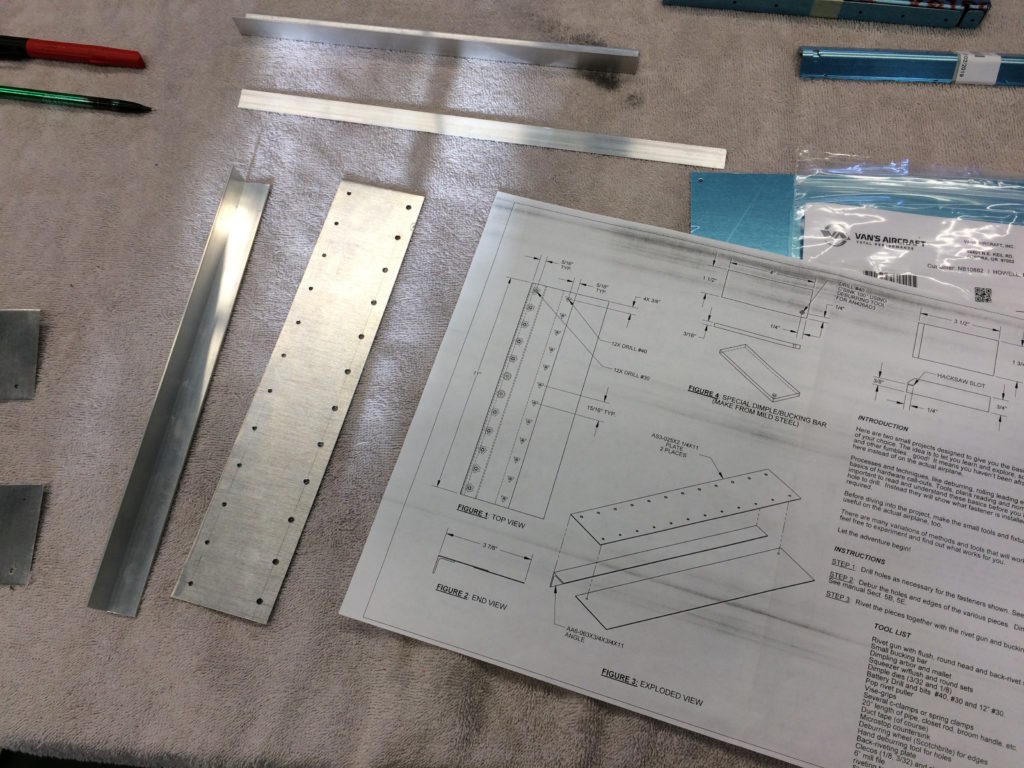

I didn’t quite finish my project, but they gave me a certificate anyway. I’m so glad I chose a Sling 2 kit with pulled rivets. I would be absolutely terrified to undertake a project with solid rivets and needing to conjure sufficient skills to wield a pneumatic rivet driver and bucking bar to achieve 14000-plus decent – let alone perfect – results. OMG!