Upholstery work takes a bit of courage and determination – at least for me it does. A big part of the work involves trimming the vinyl leatherette-like covering to fit the center console and then bonding pieces of material to some rather sizable and awkwardly shaped panels – everything is frighteningly sticky with spray adhesive.

I got through it and it all seems to look rather nice. I can’t say I’d do it the same way again, but at the same time, I don’t exactly know what I’d have done differently. You’ve just got to do the best you can.

All of the center upholstery pieces came in a kit, along with fiberglass-backed side panels, seat and seat back cushions, and carpet panels for the floor and luggage compartment. The seats cushions are covered with genuine leather and stitched by professionals. I got to choose the colors. Methinks it’s going to be a rather sporty and plush setup for this little 2-seater. Oh well! What can I say?

Once the rear portion of the center console was covered, it seemed a good time to put it into position. The inside seatbelts pass through, so it was time to assemble those to their anchors. I haven’t riveted the rear console yet – just clecos for now.

The front console panels have 3 sections. The top panel of the LH side is removable for inspections, as are 4 other square panels – 2 of which are covered with the vinyl. The 2 forward most panels are painted, along with 2 panels for the baggage area.

Bonding the covering to the RH side panel was the biggest challenge. The section of material was large enough to be unwieldy. Working conditions inside the CF were awkward. I did, however, manage to lay in the material and get it satisfactorily positioned. I’m happy to have that task in my rearview mirror.

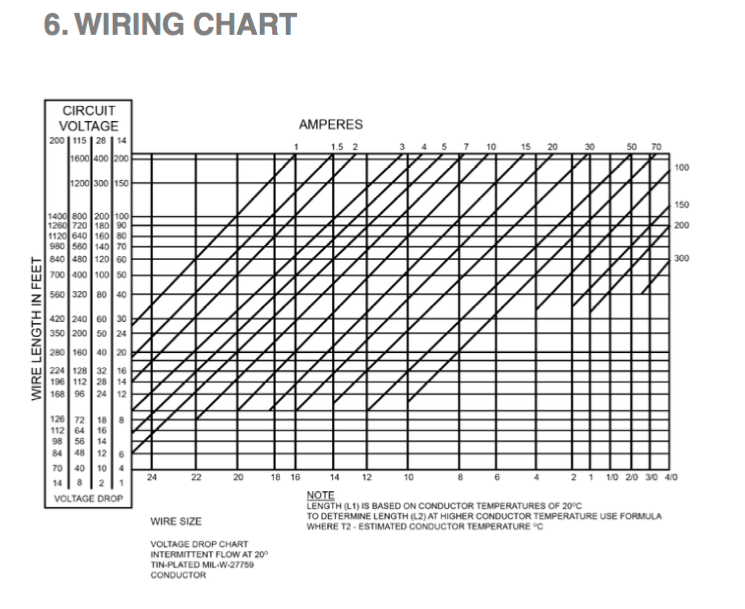

This seemed a good time to complete more of the wire connections to the rear fuselage (RF) section for the tail beacon and electric pitch trim servo. The PVC jacketed wires in the RF were routed and secured as part of the factory quick-build (QB). My custom avionics harness was provided with “pigtail” connectors. I connected the wires of the pigtail to the fuselage wires with Raychem D-436 series butt splice connectors. The connectors are a bit expensive and a special crimp tool is required. I believe the resulting connections are more than satisfactory. As usual, I insulate and protect the connections and secure them from movement.