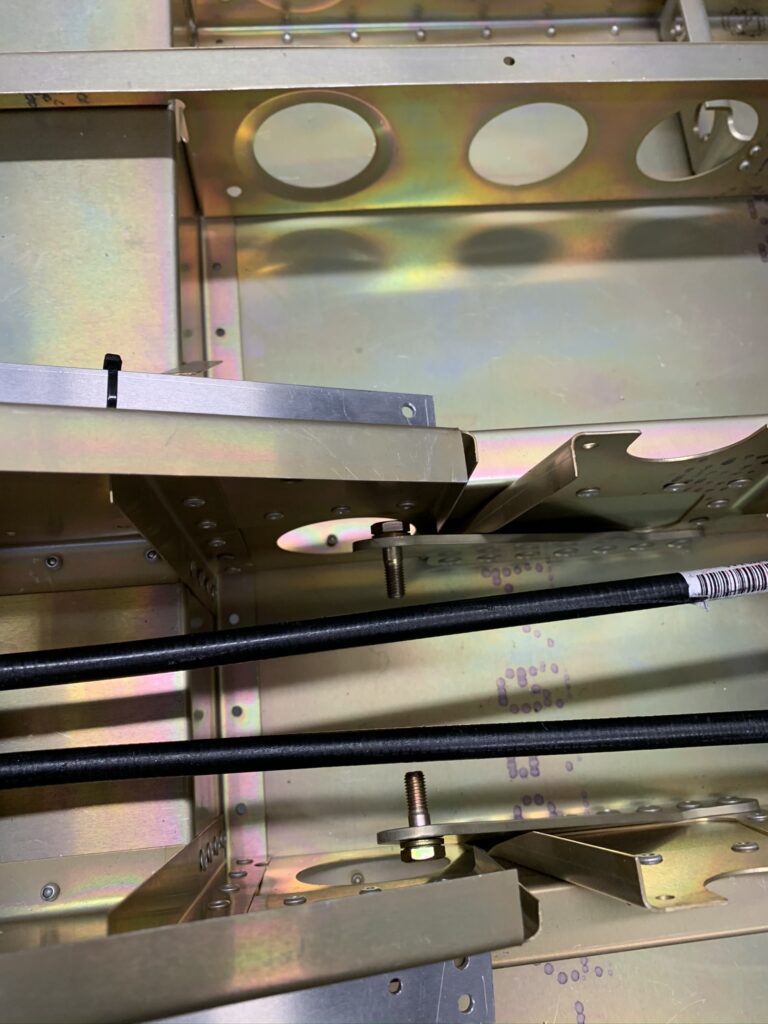

Work in the center fuselage continued with trial fitting of the rudder pedal tubes. It’s looking good. Initially, the pilot-side (LH) mounting brackets were easily positioned and the 4,0 x 10mm rivets dropped easily into most of the holes. And, after clearing a bit of paint in the holes, the rest of the rivets fit as well.

The flight control linkages rely heavily on composite Vesconite bushings, or bearings, depending on how you want to think about their purposes at different places around the airframe. I’ve known for some time, after reading accounts and watching videos posted by other Sling builders, that getting smooth, friction-free action of the controls takes some care. Some folks use the expression – black magic.

These bushings are supposedly designed to be self-lubricating. That’s all well and good, but I know some builders have resorted to supplemental lubrication. I’m trying to avoid greasy, oily, dirt-collecting areas inside the cabin if I possibly can. I’m having some luck – so far.

Two key factors need careful attention – clearance and alignment. Having enough, but not too much clearance, makes alignment slightly less critical. Buttery smooth operation, without additional lubrication, seems to be achievable.

Opening up the U-shaped retainer areas in the floor brackets and the top caps, so that no squeezing of the captured bearings occurs, makes all the difference. I used a small sanding drum on my Dremel tool at a low RPM setting. Eventually, I was able to capture the bearings in the brackets without causing any pinching of the bearing around the pedal tubes.

Next, I used some fine sandpaper around a piece of dowel to relieve a small amount of material from the bearing’s inner surface, particularly at the edges of where a saw had cut them in half. They were once circular and then cut into halves. Some cuts were better than others, but it’s not unusual to find a slight overhang from one or both halves that narrows the bearing bore at the seams where the halves meet when they’re captured in the brackets. Just a slight amount of narrowing can cause binding.

After repeated cycles of fitting and filing, the result is smooth, friction-free operation.

The rudder pedal tubes came nicely coated with gray primer. Areas on the tubes were masked from paint where the bearings ride. Except – one of the masking areas is misplaced by 1cm. I’d read about this, and sure enough, when I measured I found the off-by-1cm error too. The Vesconite bearings are designed to ride directly on the steel. Relatively soft paint would likely gum up the bearing and defeat the self-lubricating properties. I put some protective masking tape around the tube and used a strip of fine sandpaper to precisely remove additional paint.

Last, but not least – I can see how the Sling-branded rudder pedals are going to look. I think it’s much cooler than the plain T-bars. It took almost 6 months after my quick-build kit was delivered to finally get all of the pedal parts. That was a full year after I’d placed my quick-build order, which included the option. All’s well that ends well.

The Sling-branded pedals are essentially the same as the ones for toe-brakes, except that they are mounted on the standard pedal tubes and the hand-brake configuration is used. The toe-brake option has different pedal tubes, different brackets on the floor and no hand-brake. I know because I got a bunch of those parts. I worked with the factory and eventually got all of the parts I actually needed for my pedals.