It may not seem like a big deal, but having the fuselage safely off of the workbench, where it had been (somewhat precariously) perched, is a great relief and a meaningful milestone. It’s now in a position where I can work inside the center fuselage – comfortably and confidently.

The fuselage spent months sitting on the wooden structure that held it inside the sea shipping container. Then it sat for weeks on a workbench and up on some blocks that I was constantly concerned might cause great damage if the structure should somehow roll forward or backward on those blocks.

With the main landing gear in place and some help from my wife and also from my friend Charlie, the three of us were able to remove another wooden shipping structure at the tail, clear the blocks and the workbench from underneath the center fuselage and set the whole business down on the floor. The tail is supported by a padded sawhorse. Joy! Joy!

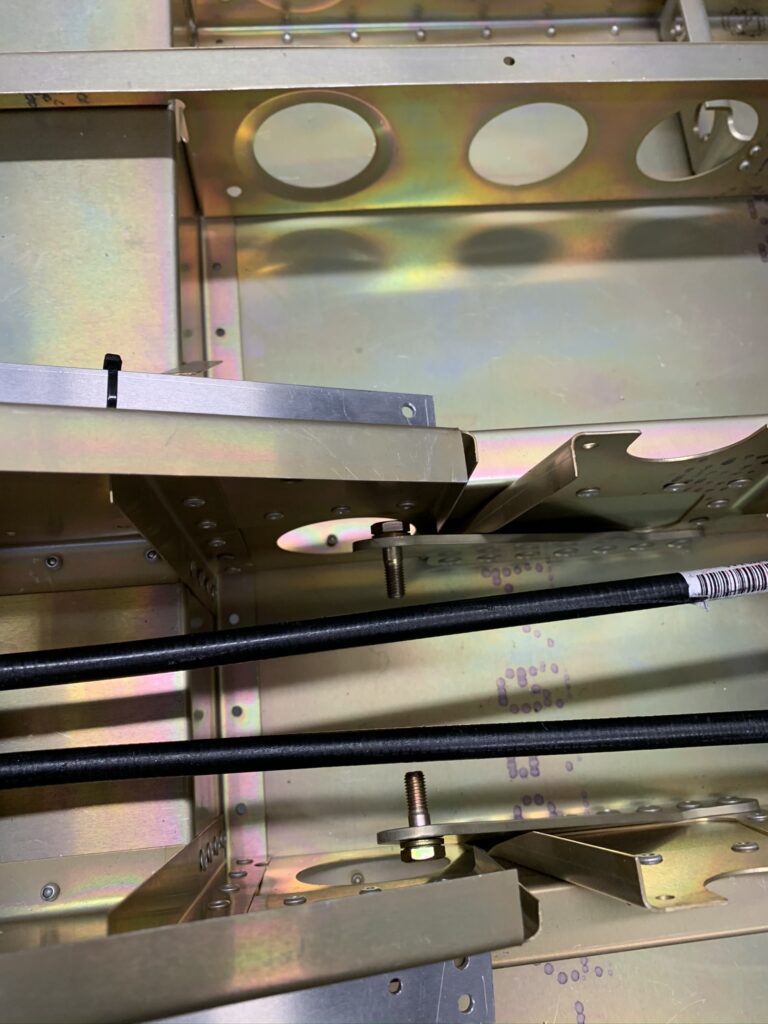

I’ve been waiting for months to work inside the center fuselage. I did the first bit of work right away – installing the center seatbelt anchor bolts into the brackets where they should have been placed by the factory – before the brackets were riveted to the CF structure. It’s clearly called out in the construction manual, but the step was forgotten.

At first, I thought I would have to unrivet both center brackets in order to get the bolts into position. But, I eventually became hopeful that I could flex the brackets just far enough to slip the bolts in. Yes! It worked. Good thing too, because it really would have been nearly impossible for me to re-rivet the brackets with conflicting structure in the way. I’m so glad I went ahead and attempted positioning the bolts as I did. Done!

I have the same factory-forgot-the-bolts issue with the outer anchor brackets, but at least there’s ample space to drill out and re-rivet. There’s no way I can flex those outer brackets enough to get the bolts where they need to be. The structure in that area is far too stiff.